FLOIL Product Information

Specialty synthetic lubricant with high functionality

Search by product categories

Search by application keywords

- To increase the durability of resin sliding parts and resin/metal sliding parts(Functional grease/oil)

- To improve the extreme-pressure properties of metal sliding parts(Mechanical grease/oil)

- To increase the durability of contacts(Contact grease/oil)

- To stabilize the contact resistance of contacts(Contact grease/oil)

- To improve shock mitigation properties(Torque damper grease)

- To improve lubricity and multi-wearability against metals(Impregnating oil)

- To eliminate oil bleeding(Mechanical Grease/Oil)

- To eliminate oil separation of oil layer in grease(Mechanical Grease/Oil)

- To control high-torque motions(Torque damper grease)

- To suppress the attacks on resin(Impregnating oil)

- To reduce any attack on plastic(Mechanical Grease/Oil)

- To reduce any attack on plastic(Fluorine grease)

- To prevent sulfurization of contacts(Contact grease/oil)

- To prevent oxidation of contacts(Contact grease/oil)

- To prevent the carbonization of grease due to arching(Contact grease/oil)

- To retain electrical conductivity while also having lubrication(Conductive grease)

- To prevent friction while taking the ground(Conductive grease)

About Customization

Our products can be customized to suit your needs. Please let us know your requirements.

Please click here for enquiriesMechanical Grease/Oil

Make your products smoother and more sophisticated with a longer lifespan.

Innovative mechanical grease used for more than 50 years since our founding.

Our mechanical grease/oil have been widely used for sliding parts, rotating shafts, gears, bearings and such for electronic mechanisms, precision devices, automobiles etc. We have lined up many product variations to satisfy a wide variety of requirements and accommodate low to high operating temperatures.

Our products can be used stably with various materials including rubber, resin and metal. Colored products are also available. Our comprehensive services include proposals—for example, a proposal on dispensers that prevents errors in use and improves productivity—and other backup services.

Features of mechanical grease / oil

Development and commercialization of pioneering functions

As a professional group of experts on grease, Kanto Kasei has been the pioneer in the industry, having developed various products one after another including the PAO, a series of synthetic hydrocarbon-based grease that is non-diffusive and non-separating. The company has succeeded in adding values to final products by thoroughly pursuing the basic performance required for functional grease and imparting new functions. Our efforts include the improvement of sound dampening qualities that match with functional materials and the improvement of durability of slide mechanisms.

These efforts have led to establish the position of our products as the functional members, playing the central roles in creating the product performance, beyond the category of secondary material as conventionally regarded in the electronics materials industry.

Abundant product line-up and high speed product development

Kanto Kasei’s mechanical grease has solved the-state-of-the-art issues in the electronics materials industry. The main resource that drives the success is our rapid response to our customers backed by development capabilities. Each personnel in charge listening to the technological needs of our customers is also a competent engineer. In Kato Kasei, customers are supported by “sales engineers”, rather than by mere sales persons.

Our sales engineers, well familiar with technological accumulation, are capable of personally engaging in the development of the best suited products to be proposed to our customers. This is evidenced by the number of the developed products well in excess of one thousand. Please do not hesitate to consult with us on any issues that have been given up as unsolvable, such as sound dampening, durability, life extension, oil dispersion and prevention of bleeding.

Product matrix by applications

- Task

- Recommendation

- Usage Example

- Wear & tear occuring at the resin sliding part. Not durable.

- Recommendation : General Grade

- Usage Example : Gears

- Rubbing noise generated during sliding.

- Recommendation : Noise reduction Grade

- Usage Example : General sliding products such as OA equipment and mechanical parts

- Surroundings smeared due to oil bleed.

- Recommendation : Non-diffusing Grade

- Usage Example : Optical equipment, vehicle interior, interior panel

- Oil seeping out.

- Recommendation : Non-separating Grade

- Usage Example : Optical equipment, vehicle interior, interior panel

- Higher resistance in a low temperature environment.

- Recommendation : Cold resistant Grade

- Usage Example : Vehicle interior related products, products for cold regions

- Poor durability on metal sliding parts.

- Recommendation : Metal resistant Grade

- Usage Example : Metal sliding parts that require high durability

Our products can be customized to suit your needs.

Please click below for enquiries on "mechanical grease/oil".

We have also uploaded implementation examples for your reference.

Contact Grease/Oil

Friendly to switches. Protecting switches. Extending the lifespan of switches

The use of the FLOIL contact grease provides the following advantages:

- Improvement in wear resistance of contact terminals.

- Corrosion prevention through contact protection.

- Improved contact stability through wear prevention.

We offer a wide selection of products to meet our customers’ needs, including contact shapes, materials, loads, electric current and temperature ranges. Special types are available including an arc-resistant grade and low-temperature grade. Several ten types of contact grease, semi-grease and oil are available.

The features of “contact grease / oil”

Product line-up

Various contact greases are available to correspond to various shapes and applications including the above.

Corrosion resistance

Contact greases, designed for materials such as copper and silver, are available. Proprietary additives protect contacts from sulfurization and oxidation.

Arc resistance

An arc-resistant grade, imparted by special additives, is available. Also available is a fluorine-based contact grease to prevent carbonization. They are widely used for on-vehicle, large-current switches.

Excellent temperature characteristics

Our products can be used in a wide temperature range from low to high temperatures. We have succeeded in developing an olefin-based grease with excellent low-temperature properties, and this grease, capable of preventing chattering at low temperatures, has been used for on-vehicle, small-current switches.

For use under special environments

Our line-up includes products used under severe conditions, in which high-temperature evaporation and chemical attacks must be prevented.

Product matrix by applications

- Task

- Recommendation

- Usage ExampleUsage Example

- Unstable connection(conduction) of contact parts.

- Recommendation : General Grade

- Usage Example : Inspection / detection switches

- Wear & tear occuring on areas with grease applied.

- Recommendation : High durability Grade

- Usage Example : Sliding switches

- Unstable silver connection(conduction) of silver due to sulfurization.

- Recommendation : Anti-sulfuration Grade

- Usage Example : Vehicle switches, sliding switches

- Unstable ON/OFFin low temperature environment (low temperature chattering).

- Recommendation : Low temperature specialization Grade

- Usage Example : Vehicle switches, sliding switches

- Grease carbonization due to arcing.

- Recommendation : Arc resistant Grade

- Usage Example : Vehicle switches, industrial machinery switches

Our products can be customized to suit your needs.

Please click below for enquiries on "contact grease/oil".

We have also uploaded implementation examples for your reference.

Conductive Grease

The main component in grounding. For parts requiring conduction and lubrication.

Reliable solution for conductive mechanism.

The main component in grounding. For parts requiring conduction and lubrication. Reliable solution for conductive mechanism.

Made using special conductive powder, this grease is an excellent conductor of electricity. It was developed to meet the needs for the grease that can eliminate static, prevent static charge, allow currents to flow and provide lubrication that emerged due to the increase in use of resins, weight reduction and downsizing of mechanical parts, as general grease is non-conductive. The grease has made substantial contribution in the field of precision parts for OA appliances and optical devices.

Features of conductive grease

High conductivity and high lubricity

Highly conductive grease applicable to parts requiring high conductivity. Our line-up includes a high-lubrication type for parts requiring further lubricity.

Products having the capabilities of both conductivity and lubrication.

They are best suited for the parts requiring both wear prevention and lubricity. The implementation examples include improved conductivity in photoreceptor drums of OA appliances and grounding of single-lens reflex camera lens barrels.

Product matrix by applications

- Task

- Recommendation

- Usage Example

- Static electric removal through grease.

- Recommendation : Conductive-focus Grade

Lubrication-focus Grade - Usage Example : Photoreceptor drums for OA equipment, interchangeable lenses for digital cameras

Our products can be customized to suit your needs.

Please click below for enquiries on "conductive grease".

We have also uploaded implementation examples for your reference.

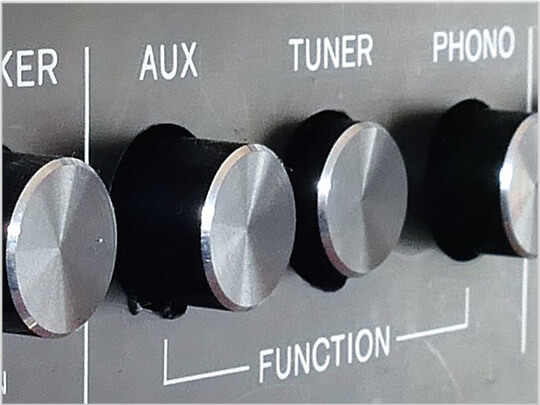

Torque/Damper Grease

Creation of excellent touch and premium feeling

Torque / damper grease exploits its high viscosity to intentionally suppresses lubricity and sliding properties, the intrinsic nature of grease, making itself suitable for providing sound-dampening, a refined feel and impact relaxation.

This grease is used in a wide range of fields, including automotive electrical components, electronic controllers, optical devices, electronic music instruments and home electrical appliances. Once applied, a small amount of this grease completely changes the product characteristics without changing its mechanical structure.

For example, the air volume controller of an automotive air conditioner which had been making an unpleasant clattering noise, was changed to make a quiet ticking sound with a smooth operational feeling by mere application of the torque grease.

The zoom lens for high-end single-lens reflex cameras and binoculars, for example, can be adapted for light to heavy operational feeling by simply changing the type of grease.

Features of "torque / damper grease"

From light to heavy operational feeling

Our wide lineup includes grease for low-torque products requiring light operational feeling, and for high-torque products that create heavy operational feeling, and can accommodate any need for fine touches.

Elimination of rasping sound, while conferring a smoother feel.

It is possible to further reduce the shock mitigation effect on hammering sound caused by colliding parts such as on dotting mechanism Furthermore, it would confer a premium feel when handled.

Product matrix by applications

- Task

- Recommendation

- Usage Example

- Knocking sound generated during sliding.

- Recommendation : Noise reduction Grade

- Usage Example : Vehicle air conditioner air volume controller

- Vibration occuring when parts are in contact.

- Recommendation : Damper Grade

- Usage Example : Micro speaker coil (prevents disconnections due to vibration)

- Produce proper tactile feel during product operation.

- Recommendation : Tactile Grade

- Usage Example : Sliding mechanism for electronic piano keyboard, camera zoom lens mechanism, High-end audio amplifier controls

Our products can be customized to suit your needs.

Please click below for enquiries on "torque / damper grease".

We have also uploaded implementation examples for your reference.

Impregnating Oil

Lineup of oil accommodating requirements for wide temperature range, extreme pressure and silence

FLOIL oil for impregnated metals was developed in 1975 as an impregnating oil for small sintered bearings and has been used since then as the standard oil by bearing manufacturers over the world.

With recent downsizing and noise reduction of motors, as well as the increasing use of resin for peripheral parts, impregnating oils are required to have increasingly stringent temperature characteristics, sound dampening properties and stabilization with resin. Please try the impregnating oils of Kanto Kasei, the industrial pioneer with a long history of achievements.

Features of impregnating oil

Oil with high viscosity index that is rare in the industry

Using synthetic hydrocarbon oil that is stable against resin as a base, our lineup of oils achieves the viscosity index of 230. Various grades of viscosity are available to be used at a wide range of temperatures. The impregnating oil minimizes the viscosity change due to temperature variation.

Extreme-pressure grade with excellent wear resistance

Special extreme-pressure agents decreases metal wear. Our lineup include products with excellent extreme-pressure and sound dampening properties for the parts under high load and/or requiring sound dampening properties.

Product matrix by applications

- Task

- Recommendation

- Usage Example

- Add lubricity with sintered bearings.

- Recommendation : General Grade

- Usage Example : Sintered metal (General)

- Resin cracks occur around motor component.

- Recommendation : Plastic resistant Grade

- Usage Example : Sintered metal (General)

- Wear & tear occurs on sintered bearing.

- Recommendation : Abrasion resistant Grade

- Usage Example : Sintered metal (General)

- Large variance of sliding load during temperature changes.

- Recommendation : High viscosity index Grade

- Usage Example : Sintered metal (Automotive)

Our products can be customized to suit your needs

Please click below for enquiries on "impregnating oil".

We have also uploaded implementation examples for your reference.

Thermal Compound

Expert in heat dissipation

<Amazing heat-release performance> <Protecting electronics devices from heat>

Heat is inevitably generated in electronic devices. Prolonged heat generation accumulates damage in the devices. Kanto Kasei has developed a heat-release compound to protect such devices from heat.

When applied between a heat source and heat sink, our heat-release compound decreases the thermal resistance and contributes to more effective heat dissipation.

Features of “thermal compound”

Meeting our customers' needs

The compound in paste form allows the thickness to be easily controlled, which makes a significant difference from heat-release sheets having the same thermal conductivity. The compound can be applied using a dispenser and can also be reworked, unlike adhesives, providing excellent usability.

Product matrix by applications

- Task

- Recommendation

- Usage Example

- PCB board heat dissipation.

Difficulty in attaching thermal sheets. - Recommendation : Standard type (0.83w/m・k)

High thermal conductivity type (2.1w/m・k) - Usage Example : Contact surface between IC and heat sink

Our products can be customized to suit your needs

Please click below for inquiries on “thermal compound”.

We have also uploaded implementation examples for your reference.

Fluorine Grease

From the ocean depth to outer space

Fluorine grease is a superb quality grease that can be used under severe conditions that conventional grease cannot withstand.

We strive to fully exploit the advantage of fluorine and offer products to our customers.

Features of “fluorine grease”

Excellent lubricity and temperature characteristics

The fluorine grease exhibits flat characteristics from low to high temperatures. Thermal resistance, cold tolerance, oxidation resistance and long operating life are eternal subjects for lubricants. Our fluorine grease, FLOIL, aims to become the ideal solution by fully exploiting the advantages of fluorine. With its non-carbonizing feature, it provides excellent performance in mechanisms and contacts under severe on-vehicle conditions.

Product matrix by applications

- Task

- Recommendation

- Usage Example

- Provide lubricity to components in high temperature.

- Recommendation : Heat resistant Grade

- Usage Example : Vehicle electrical components, sliding parts near OA equipment's fuser

- Provide lubricity to components in low temperature.

- Recommendation : Cold resistant Grade

- Usage Example : Vehicle electrical components, products for cold regions

Our products can be customized to suit your needs.

Please click below for enquiries on “fluorine grease”.

We have also uploaded implementation examples for your reference.